Aviation MRO

Aircraft endure a lot of abuse. Bird-strikes, hail-damage, ground support equipment collisions and debris kicked-up from the tires during take-off and landing, are all responsible for constant dents and dings to the airframe. These can keep an aircraft grounded. It’s bad for safety and bad for business. 8tree’s dentCHECK tool empowers aircraft technicians and structures engineers to perform fast, accurate and consistent damage-mapping.

Aircraft endure a lot of abuse. Bird-strikes, hail-damage, ground support equipment collisions and debris kicked-up from the tires during take-off and landing, are all responsible for constant dents and dings to the airframe. These can keep an aircraft grounded. It’s bad for safety and bad for business. 8tree’s dentCHECK tool empowers aircraft technicians and structures engineers to perform fast, accurate and consistent damage-mapping.

Aerospace

An aircraft is held together by millions of small rivets, or fasteners. If fasteners are not flush with the surrounding airframe, then very bad things can happen. Problems range from aerodynamic drag-induced fuel-inefficiency to structural-fatigue that comprises the airframe leading to potentially catastrophic consequences. 100% inspection of final assembly thus plays a vital role in quality assurance. 8tree’s fastCHECK tool increases fastener inspection efficiency in the manufacturing and QA stages and drastically cuts expensive rework costs.

An aircraft is held together by millions of small rivets, or fasteners. If fasteners are not flush with the surrounding airframe, then very bad things can happen. Problems range from aerodynamic drag-induced fuel-inefficiency to structural-fatigue that comprises the airframe leading to potentially catastrophic consequences. 100% inspection of final assembly thus plays a vital role in quality assurance. 8tree’s fastCHECK tool increases fastener inspection efficiency in the manufacturing and QA stages and drastically cuts expensive rework costs.

Turbine Blade Manufacturing

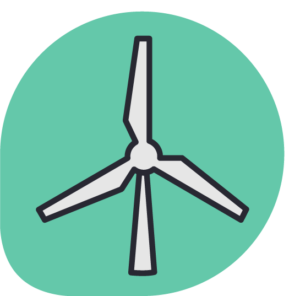

Wrinkles and creases are the bane of a blade manufacturer. These small wave-like disturbances in cured fiber laminate have a ripple effect on operating inefficiencies. Many wrinkles per blade, three blades per wind tower, thousands of towers per farm, hundreds of new farm deployments per year…you get the picture. 8tree’s waveCHECK instantly reports a wrinkle’s critical height-width ratio, thereby slashing Quality Control time and costs.

Wrinkles and creases are the bane of a blade manufacturer. These small wave-like disturbances in cured fiber laminate have a ripple effect on operating inefficiencies. Many wrinkles per blade, three blades per wind tower, thousands of towers per farm, hundreds of new farm deployments per year…you get the picture. 8tree’s waveCHECK instantly reports a wrinkle’s critical height-width ratio, thereby slashing Quality Control time and costs.

Photo Paper Manufacturing

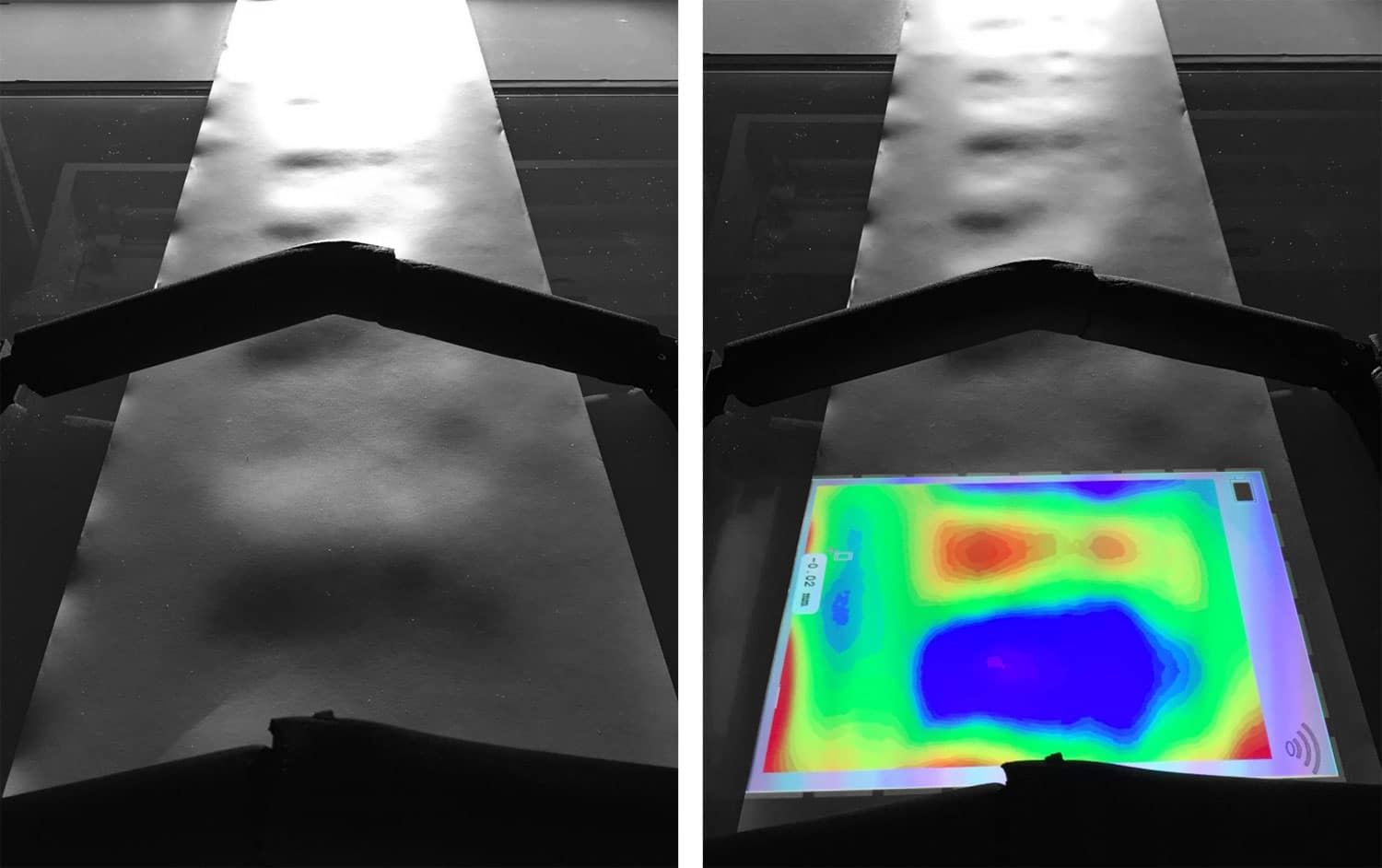

Production of professional photopaper is a very delicate process. Slight surface undulations in the thin photopaper create the appearance of ‘bags’, ‘hills’ and ‘valleys’. This renders the paper useless. 8tree’s tool conclusively quantify the undulations. This drives improvements in the manufacturing workflow, thereby reducing rework costs and waste in the photopaper supply chain.

Production of professional photopaper is a very delicate process. Slight surface undulations in the thin photopaper create the appearance of ‘bags’, ‘hills’ and ‘valleys’. This renders the paper useless. 8tree’s tool conclusively quantify the undulations. This drives improvements in the manufacturing workflow, thereby reducing rework costs and waste in the photopaper supply chain.