CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, NOVEMBER, 29, 2023

Over the past year, 8tree’s dentCHECK-as-a-Service (daaS) business has digitally mapped and reported over 10,000 dents across a dozen commercial aircraft. In response to growing market demand for such services, 8tree is building a global network of service partners, while also scaling 8tree’s internal services team. Flying Colours Aviation (FCA) is the latest industry expert to join 8tree’s service network.

Starting September 2023, Flying Colours Aviation becomes an 8tree Certified Service Partner offering dentCHECK-powered on-demand airframe inspection service in Australia and New Zealand.

“We are always staying at the forefront of innovation to support our operations, dedicated to enhancing the quality of services offered to our customers. 8tree’s dentCHECK is a veritable ‘game changer’ within the industry and a transformative addition to FCA’s toolkit. The integration of advanced technology in a practical and highly efficient manner is exemplified by dentCHECK”, said Lloyd Armstrong, Project Manager at Flying Colours Aviation.

“The speed, precision, and effortless acquisition of measurements enabled by dentCHECK, is set to revolutionize the way FCA manages and records exterior damage for airlines and operators. Traditionally, obtaining these data would take an order of magnitude longer.”

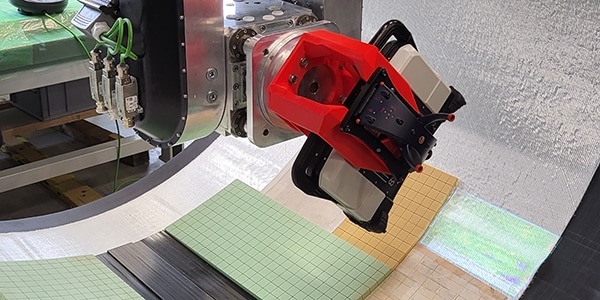

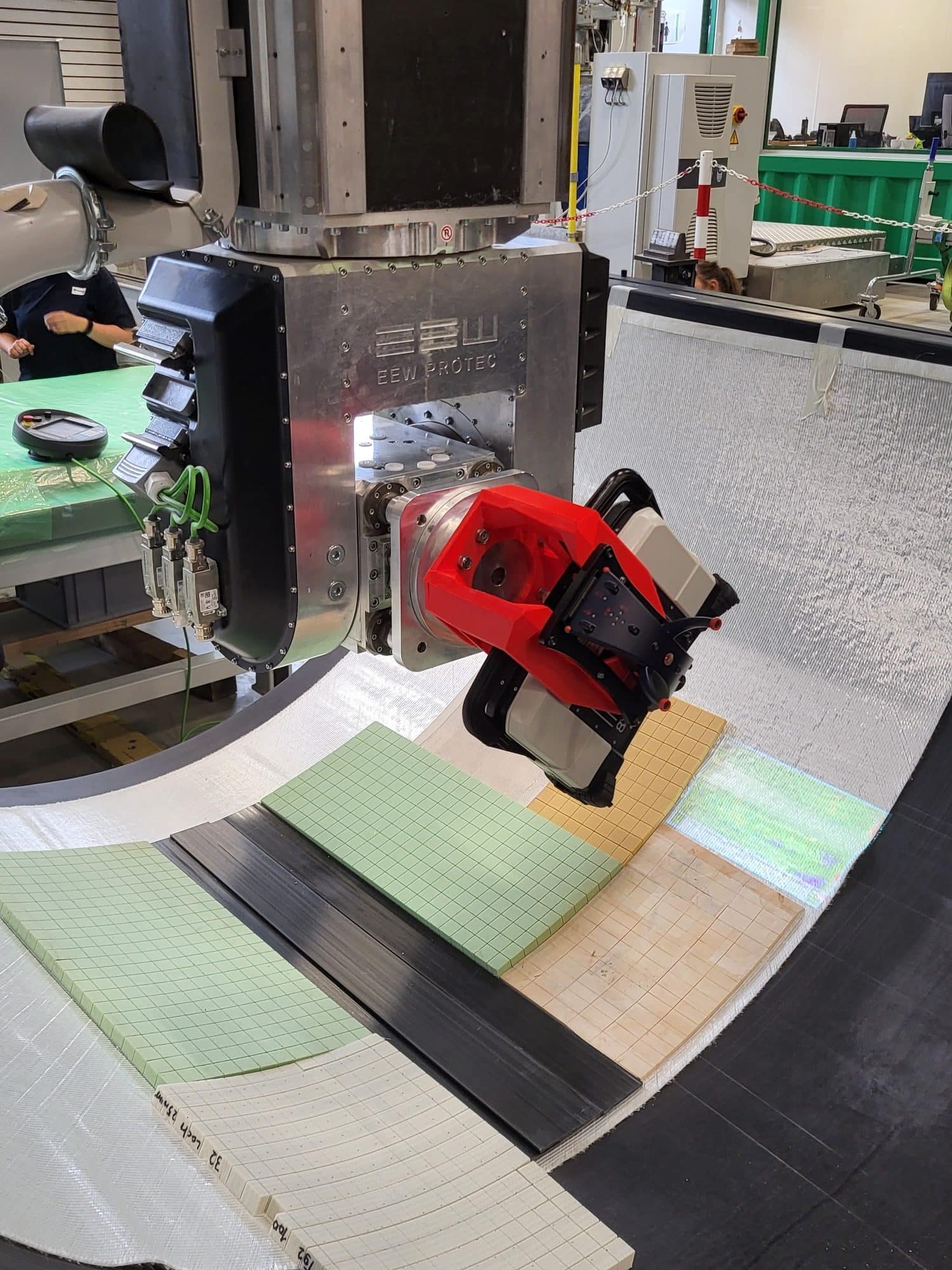

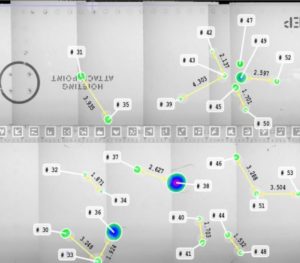

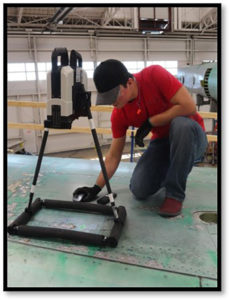

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

About Flying Colours Aviation

Flying Colours Aviation (FCA) is a leading aircraft repainting provider in the Australasia region, servicing the repaint and corrosion control requirements of civil and defence aircraft and operators. With the capability to strip and repaint aircraft up to Boeing 757-200 and C-130J at our Townsville facility in Queensland Australia. FCA has a proven track record providing a full suite of high quality, innovative and environmentally sustainable services that ensures all aircraft are repainted to meet or exceed customer expectations.

For more information, visit fca.aero