8tree’s dentCHECK-as-a-Service program grows with the addition of Flying Colours Aviation as an 8tree Certified Service Partner. dentCHECK-as-a-Service delivers on-demand airframe spot-checks and nose-to-tail mapping for lease transitions and catastrophic hail damage scenarios.

8tree’s dentCHECK-as-a-Service program grows with the addition of Flying Colours Aviation as an 8tree Certified Service Partner. dentCHECK-as-a-Service delivers on-demand airframe spot-checks and nose-to-tail mapping for lease transitions and catastrophic hail damage scenarios.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, NOVEMBER, 29, 2023

Over the past year, 8tree’s dentCHECK-as-a-Service (daaS) business has digitally mapped and reported over 10,000 dents across a dozen commercial aircraft. In response to growing market demand for such services, 8tree is building a global network of service partners, while also scaling 8tree’s internal services team. Flying Colours Aviation (FCA) is the latest industry expert to join 8tree’s service network.

Starting September 2023, Flying Colours Aviation becomes an 8tree Certified Service Partner offering dentCHECK-powered on-demand airframe inspection service in Australia and New Zealand.

“We are always staying at the forefront of innovation to support our operations, dedicated to enhancing the quality of services offered to our customers. 8tree’s dentCHECK is a veritable ‘game changer’ within the industry and a transformative addition to FCA’s toolkit. The integration of advanced technology in a practical and highly efficient manner is exemplified by dentCHECK”, said Lloyd Armstrong, Project Manager at Flying Colours Aviation.

“The speed, precision, and effortless acquisition of measurements enabled by dentCHECK, is set to revolutionize the way FCA manages and records exterior damage for airlines and operators. Traditionally, obtaining these data would take an order of magnitude longer.”

“Flying Colours Aviation’s technical understanding of the airframe and their established reputation with aviation operators in Australia and New Zealand made them an obvious choice for us”, said Arun Chhabra, CEO at 8tree. “We are delighted to have them join 8tree’s global service network. The combination of Flying Colors Aviation and 8tree’s 3D dent-mapping service is certain to empower customers in the region with accelerated turn-around-times and digitalized damage-records.”

“Flying Colours Aviation’s technical understanding of the airframe and their established reputation with aviation operators in Australia and New Zealand made them an obvious choice for us”, said Arun Chhabra, CEO at 8tree. “We are delighted to have them join 8tree’s global service network. The combination of Flying Colors Aviation and 8tree’s 3D dent-mapping service is certain to empower customers in the region with accelerated turn-around-times and digitalized damage-records.”

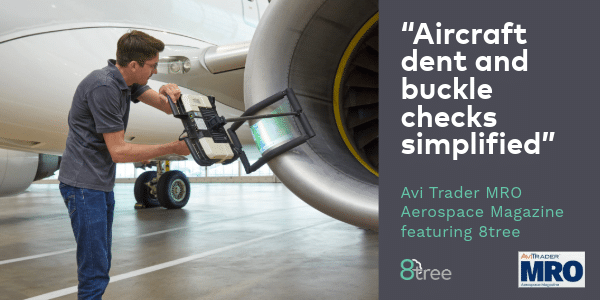

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

About Flying Colours Aviation

Flying Colours Aviation (FCA) is a leading aircraft repainting provider in the Australasia region, servicing the repaint and corrosion control requirements of civil and defence aircraft and operators. With the capability to strip and repaint aircraft up to Boeing 757-200 and C-130J at our Townsville facility in Queensland Australia. FCA has a proven track record providing a full suite of high quality, innovative and environmentally sustainable services that ensures all aircraft are repainted to meet or exceed customer expectations.

For more information, visit fca.aero

Download Press Release as PDF

Download Press-Kit

8tree’s dentCHECK-as-a-Service™ digitally mapped and reported hail damage on the control surfaces of B777 and A220 aircraft operated by Swiss International Air Lines.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, NOVEMBER 30, 2023

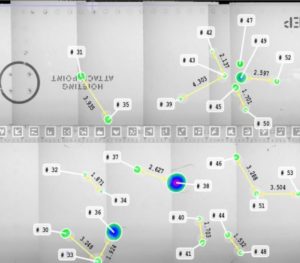

More than 1,500 dents were digitally mapped and reported by 8tree’s dentCHECK-as-a-Service (daaS) at Swiss International Air Lines (SWISS) hangars in Zurich, Switzerland. The control surfaces of a B777 and an A220 had been damaged in a hailstorm. 8tree’s service engineers used the dentCHECK dent-mapping tool to digitally map and report all dents on the affected areas, efficiently and effectively.

More than 1,500 dents were digitally mapped and reported by 8tree’s dentCHECK-as-a-Service (daaS) at Swiss International Air Lines (SWISS) hangars in Zurich, Switzerland. The control surfaces of a B777 and an A220 had been damaged in a hailstorm. 8tree’s service engineers used the dentCHECK dent-mapping tool to digitally map and report all dents on the affected areas, efficiently and effectively.

“We are very satisfied with the service provided by 8tree”, says Claus Bauer, Head of Technical Division at SWISS. “The automated dentCHECK-tool helped us to record hail damage quickly and completely so that we could rectify it promptly. This enabled us to return the aircraft concerned to flight operations in airworthy condition as quickly as possible, which is of key importance to us as an airline.”

“We are excited that Swiss International Air Lines decided to perform the dent-mapping on two hail damaged aircraft with 8tree’s service capabilities”, said Erik Klaas, CTO, 8tree. “As the first Swiss airline, they joined the growing base of dentCHECK-as-a-Service customers who disposition hail damage affected aircraft using our dentCHECK tool. We look forward to continuing Swiss International Airlines maintenance operations.”

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

Download Press Release as PDF

Download Press-Kit

Marketing Manager

Get in contact

LinkedIn

8tree extends its automation inspection portfolio by partnering with Avinxt for robotic aviation inspection system.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, NOVEMBER 22, 2023

8tree’s 3D inspection engines can be found in the hands of human operators, mounted on drones, and integrated into robotic automation cells.

8tree’s 3D inspection engines can be found in the hands of human operators, mounted on drones, and integrated into robotic automation cells.

The automatic robotics system from Avinxt for fully automated aircraft de-icing, washing and engine wash will debut at Avinor Oslo Airport (OSL), where the robot will be built in 2024. The robot, which replaces the current manual and time-consuming processes, is faster, more environmentally friendly and more cost-effective than traditional methods.

“By integrating 8tree’s technology with our robotics system, we can scan aircraft for damage. The system performs aircraft surface inspections with extreme precision within a few hours, compared to manual processes that take several weeks. We believe this service will be in high demand from airlines and leasing companies as it will significantly reduce costs,” said CEO Ove Trøen of Avinxt.

“We are excited to work with Avinxt on this very novel robotic inspection concept”, said Erik Klaas, CTO and Co-Founder at 8tree. “Never before was it possible to automate aircraft inspection to this degree. We see a big potential not only in the case of hail damage assessment on the entire aircraft but also in cases where the aircraft changes ownership. This has always been an area with lots of debate which now can be resolved with an objective and quick process.”

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

About Avinxt

Avinxt is building the world’s biggest robot powered by green technology and artificial intelligence that will reduce cost and carbon emissions for the aviation industry. Supported by Canrig and Siemens, the world’s largest robot from Avinxt will potentially replace the current manual and time-consuming processes for de-ice, wash, engine wash and technical inspection of aircraft. The first robot is expected to be in operation at Oslo Airport in 2024.

For more information, visit avinxt.com.

Download Press Release as PDF

Download Press-Kit

Marketing Manager

Get in contact

LinkedIn

CONSTANCE, GERMANY, SEPTEMBER 16, 2023

ISO17025 Certificate

8tree, a global leader in 3D surface inspection tools, is proud to announce that its calibration laboratory based in Constance, Germany has been accredited according to ISO 17025 by the Deutsche Akkreditierungsstelle (DAkkS), the accreditation body of the Federal Republic of Germany, with the accreditation number D-K-21981-01-00.

This significant achievement underscores 8tree’s unwavering commitment to quality and precision measurements.

The ISO/IEC 17025 accreditation is a testament to a laboratory’s technical competence and ability to produce precise and accurate test and calibration data. It sets the gold standard for calibration and testing laboratories worldwide, ensuring that they adhere to the highest quality benchmarks.

“We are proud to achieve this accreditation from DAkkS, which is a testament to our continuous pursuit of excellence and quality,” said Arun Chhabra, CEO of 8tree. “This recognition further solidifies our position as a trusted partner for our customers, ensuring that our products and services are of the highest caliber, and that we continue to exceed customer expectations.”

What does ISO 17025 Accreditation Mean?

- It signifies that the laboratory technically operates with high accuracy, reliability, and consistency.

- It ensures that the laboratory has a robust quality management system in place, and an external body regularly audits its operations.

- The laboratory’s results are internationally recognized, paving the way for even more global business opportunities.

Benefits of ISO 17025 Accreditation:

- Enhanced Credibility: Clients and partners can trust the results produced by the laboratory.

- Operational Excellence: Streamlined processes lead to reduced errors and increased efficiency.

- Global Recognition: The laboratory’s results are accepted and recognized worldwide.

- Continuous Improvement: Regular audits ensure that the laboratory is always improving its processes and methodologies.

To access ‘ ‘8tree’s accreditation on the website of the Accreditation body, please visit https://www.dakks.de/en/accredited-body.html?id=D-K-21981-01-00.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

Download Press Release as PDF

Marketing Manager

Get in contact

LinkedIn

8tree’s dentCHECK-as-a-Service program grows with the addition of AMROS Global as an 8tree Certified Service Partner.

8tree’s dentCHECK-as-a-Service program grows with the addition of AMROS Global as an 8tree Certified Service Partner.

dentCHECK-as-a-Service delivers on-demand airframe spot-checks and nose-to-tail mapping for lease transitions and catastrophic hail damage scenarios.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, JULY 13, 2023

Over the past year, 8tree’s dentCHECK-as-a-Service (daaS) business has digitally mapped and reported over 10,000 dents across a dozen commercial aircraft. In response to growing market demand for such services 8tree is building a global network of service partners, while also scaling 8tree’s internal staffing. AMROS Global is the latest industry expert to join 8tree’s service network.

Starting July 13th, AMROS Global will become an 8tree Certified Service Partner offering on-demand airframe inspection service using dentCHECK, in central Europe.

“Together with 8tree, we will be able to further extend our innovative, integrated solution offering for technical management of aircraft, following. With dentCheck-as-a-Service, we will provide a never seen before structural inspection service, revolutionizing the way we perceive quality in measurement, analysis and reporting of structural damages on aircraft of all types – be it for scheduled or unscheduled inspections,” said Eros Tavani, CEO at AMROS Global.

“Together with 8tree, we will be able to further extend our innovative, integrated solution offering for technical management of aircraft, following. With dentCheck-as-a-Service, we will provide a never seen before structural inspection service, revolutionizing the way we perceive quality in measurement, analysis and reporting of structural damages on aircraft of all types – be it for scheduled or unscheduled inspections,” said Eros Tavani, CEO at AMROS Global.

“We are delighted to welcome AMROS to 8tree’s global service network”, said Howard Chung, Applications Engineering Manager at 8tree. “AMROS’ proven track-record in managing aviation assets coupled with 8tree’s widely adopted 3D dent-mapping tools, is certain to deliver faster aircraft turn-around-times for the industry”

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

About AMROS Global

We are a Flight and Ground Operations services company founded in Michigan in 1998 to serve the military and the commercial aviation world. Today, we are proud to have our own team of talented engineers and mechanics who log an average of 1,200 man-hours every day in support of aircraft maintenance tasks with clients in 4 continents.

For more information, visit amrosglobal.aero.

For recent news, follow AMROS Global on LinkedIn.

Download Press Release as PDF

Download Press-Kit

Marketing Manager

Get in contact

LinkedIn

8tree’s dentCHECK-as-a-Service program grows with the addition of VS Aviation as an 8tree Certified Service Partner.

8tree’s dentCHECK-as-a-Service program grows with the addition of VS Aviation as an 8tree Certified Service Partner.

dentCHECK-as-a-Service delivers on-demand airframe spot-checks and nose-to-tail mapping for lease transitions and catastrophic hail damage scenarios.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, SEPTEMBER 21

Over the past year, 8tree’s dentCHECK-as-a-Service (daaS) business has digitally mapped and reported over 10,000 dents across a dozen commercial aircraft. In response to growing market demand for such services, 8tree is building a global network of service partners, while also scaling 8tree’s internal service staff. VS Aviation is the latest industry services expert to join 8tree’s service network.

Beginning August 2023, VS Aviation became an 8tree Certified Service Partner offering dentCHECK powered on-demand airframe inspection service in the Middle East.

Beginning August 2023, VS Aviation became an 8tree Certified Service Partner offering dentCHECK powered on-demand airframe inspection service in the Middle East.

“Love at first sight” was the immediate response from Samer Karadsheh, Director Flight Ops Engineering, when his wife and business partner engineer; Lara Obeid, CTO, came across 8tree’s profile at MRO Europe in 2021. “This is an ingenious solution to a problem that the whole aviation industry deals with, and I personally experienced it first-hand as an Aircraft Structures Engineer dealing with aircraft skin damage”, said Samer. VS Aviation LLC is an aircraft maintenance contractor and, along with 8tree’s support, we are excited to bring dentCHECK-as-a-Service (daaS) to our clients in the Middle East. “A solution like no other”, says Lara Obeid, as evident in the reaction on the engineers’ and sheet metal mechanics faces when their dent reporting challenge is solved with a single “click”.

“VS Aviation’s deep technical understanding of the airframe has established their reputation with global aviation maintenance customers”, said Arun Chhabra, CEO at 8tree. “We are delighted to have them join 8tree’s global service network. The combination of VS Aviation and 8tree’s 3D dent-mapping service is certain to empower customers in the region with accelerated turn-around-times and digitalized damage-records.”

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

About VS Aviation

We are a Flight and Ground Operations services company founded in Michigan in 1998 to serve the military and the commercial aviation world. Today, we are proud to have our own team of talented engineers and mechanics who log an average of 1,200 man-hours every day in support of aircraft maintenance tasks with clients in 4 continents.

Download Press Release as PDF

Download Press-Kit

Marketing Manager

Get in contact

LinkedIn

Over the past decade, 8tree’s dentCHECK has successfully defined a new industry category for application-specific 3D surface inspection tools. Now, with over 150 systems deployed globally among more than 4-dozen customers, 8tree is launching the next-generation – dentCHECK2.

“Everything we do at 8tree is shaped by insights from our customers – the world’s leading MROs, Airlines and OEMs; our next-gen dentCHECK offering is no exception”, said Arun Chhabra, CEO, 8tree. “By redesigning the tool around our successfully established measurement engine, we continue to build on our core principles of simplicity, usability and efficiency. This enables us to deliver instantly actionable precision 3D measurements within seconds, at the push of a single button. Some of the numerous improvements include significantly more compact form-factor, lighter weight, built-in LTE connectivity, zero setup time and a streamlined UX. Stop by booth #4745 at MRO Americas to get a hands-on demonstration of dentCHECK2”.

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry, and recognized by all major aerospace OEMs (Airbus, Boeing, Bombardier and Embraer). It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry, and recognized by all major aerospace OEMs (Airbus, Boeing, Bombardier and Embraer). It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

From spot-checks, to hail-damage assessment, to nose-to-tail inspections during lease returns/redeliveries, dentCHECK empowers operators to assess airframe damage up to 90% faster and with 35x greater measurement accuracy and consistency than traditional methods. This has a direct impact on reducing Turn-around-Times and boosts operational efficiency. dentCHECK enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news follow 8tree on LinkedIn.

”“Everything we do at 8tree is shaped by insights from our customers – the world’s leading MROs, Airlines and OEMs; our next-gen dentCHECK offering is no exception”, said Arun Chhabra, CEO, 8tree.

Marketing Manager

Get in contact

LinkedIn

Panasonic Avionics Corporation (Panasonic Avionics) and 8tree today announced an expansion of their relationship

and availability of the dentCHECK dent-mapping and reporting service.

This press release was published on PRWeb.

The expanded service will now include support for Large Area Dent Mapping at customer locations. This builds on the existing Ad Hoc dent-mapping services offered at Panasonic Technical Service (PTS) regional line stations at Los Angeles International Airport (LAX) and London Heathrow (LHR) area airports.

The expanded service will now include support for Large Area Dent Mapping at customer locations. This builds on the existing Ad Hoc dent-mapping services offered at Panasonic Technical Service (PTS) regional line stations at Los Angeles International Airport (LAX) and London Heathrow (LHR) area airports.

The introduction of large area dent mapping service is particularly suited to hail damage scenarios and follows a series of very successful service jobs completed by Panasonic Avionics and 8tree. In the aftermath of an extreme hail event in Roswell, New Mexico late last year, several severely damaged wide-body aircraft – as many as a thousand dents each – were inspected using dentCHECK’s large area panoramic mapping feature. A comprehensive itemized digital report, containing key damage metrics, were completed in days, as opposed to the months it would have taken with traditional manual methods.

This service offering will allow Panasonic Avionics customers yet another convenient, accurate, and efficient way to protect their commercial aircraft investment, avoiding unnecessary costs and time delays. Further, the service will complement PTS’s existing line of best-in-class products and services, continuing its history of being a premier MRO service solution provider.

“We are pleased to announce the expansion of our relationship with 8tree,” said Sean Gavin, SVP of Panasonic Technical Services. “Using the 8tree scanning technologies allows us to deliver highly accurate information much more quickly than previously possible using traditional methods. This allows our passenger and cargo airline customers to make very timely, data-driven, operational decisions. Our global network, combined with 8tree technology creates a high-value, cost-effective service for dent mapping and aircraft safety solutions.”

“After the incredible results in Roswell last year, expanding the scope of our dentCHECK service relationship with Panasonic Avionics was a natural choice”, said Arun Chhabra, CEO of 8tree. “Operators will benefit from the faster, more efficient mapping of catastrophic hail damage, allowing them to make more informed decisions about aircraft serviceability and return to service, while alongside building more robust aircraft records. Working with the Panasonic Avionics team to deliver this large area mapping service, we look forward to seeing operators return their aircraft to service faster and with greater confidence.”

Panasonic Avionics supplies and services in-flight entertainment and connectivity (IFEC) systems. The company’s customer base includes more than 300 airlines located across the globe. PTS provides spares and repairs, line maintenance, and technical services at more than 50 locations globally. PTS’ customized solutions are designed to ensure equipment serviceability at the lowest possible through-life cost.

About Panasonic Avionics Corporation

Panasonic Avionics Corporation is the world’s leading supplier of in-flight entertainment and communication systems. The company pioneered the industry beginning in 1979 and has consistently introduced innovations that enable unique customer experiences and enhance airline loyalty (NPS), ancillary revenue, and operational efficiency.

Leading airlines across the world have chosen to install Panasonic Avionics IFE systems on more than 15,000 commercial aircraft and satellite Wi-Fi connectivity on over 3,400 aircraft. Panasonic Avionics’ proven systems power approximately 70% of the global IFE-equipped fleet and is supported by the largest, global support and services team utilizing OEM insights to ensure peak system performance.

Panasonic Avionics Corporation is headquartered in California with over 3,500 employees and operates in over 50 locations around the globe.

For additional information, please visit www.panasonic.aero.

About 8tree

“Precision 3D measurement as simple as taking a photo”

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented user-centric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

Marketing Manager

Get in contact

LinkedIn