Leading global MRO HAECO has implemented dentCHECK at its Hong Kong and Lake City, Florida maintenance facilities to expedite airframe damage inspection including extensive hail-damage scenarios.

This press release was published on PRWeb.

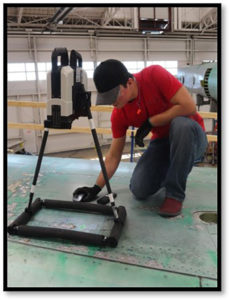

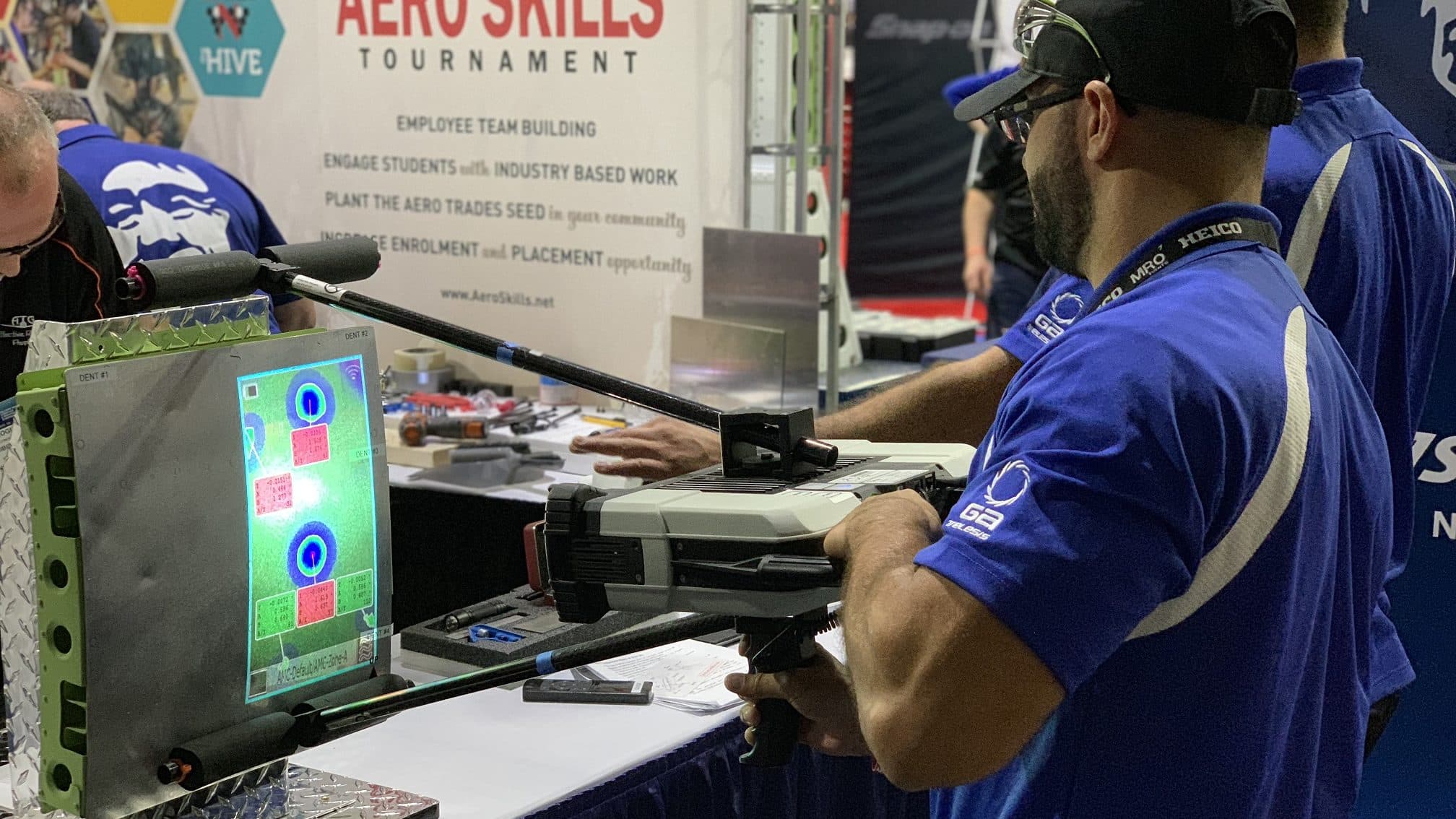

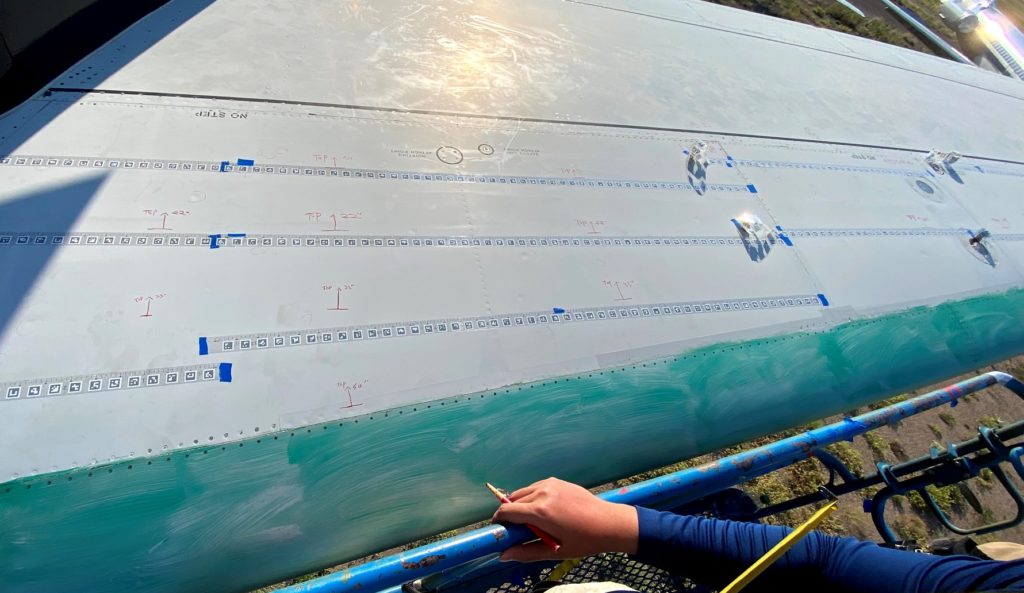

dentCHECK usage at HAECO facility in Hong Kong.

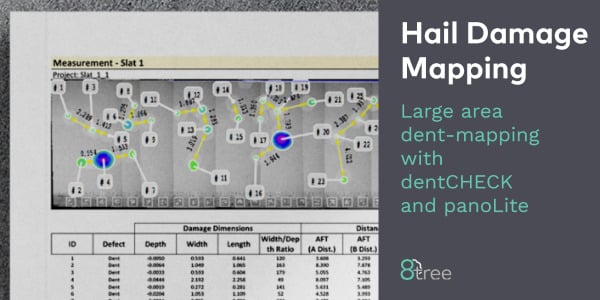

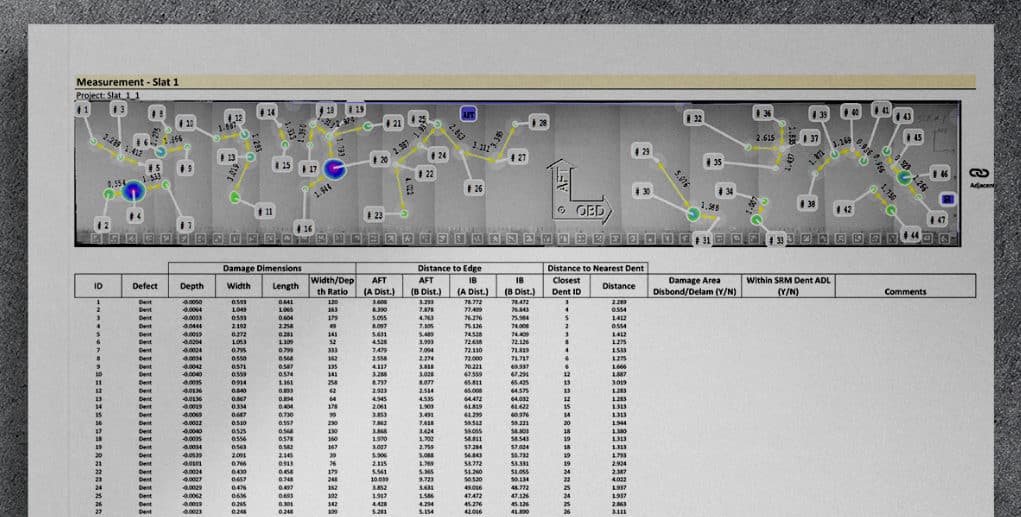

HAECO Group, one of the world’s leading aviation products and services providers, has begun using 8tree’s dentCHECK tool to enhance the efficiency and quality of its dent-mapping activities. In particular, HAECO Hong Kong and HAECO Americas are already making use of dentCHECK’s new automatic large-area mapping capability to drastically reduce the time taken for inspecting incoming hail-damaged aircraft.

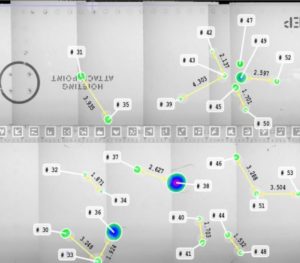

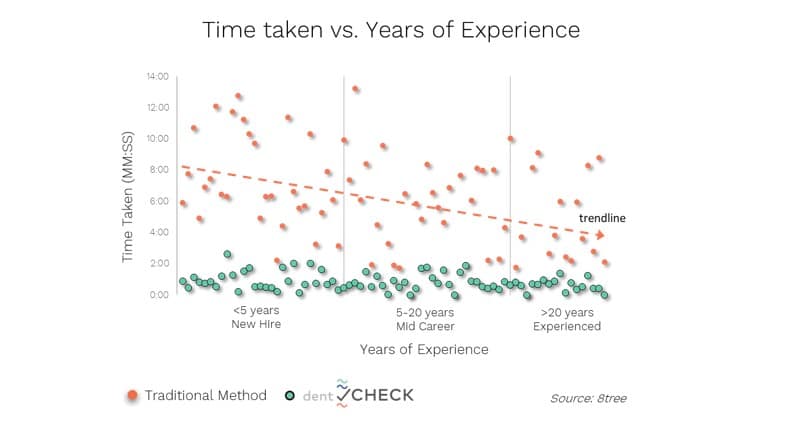

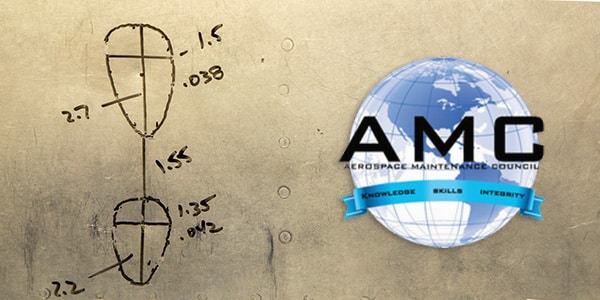

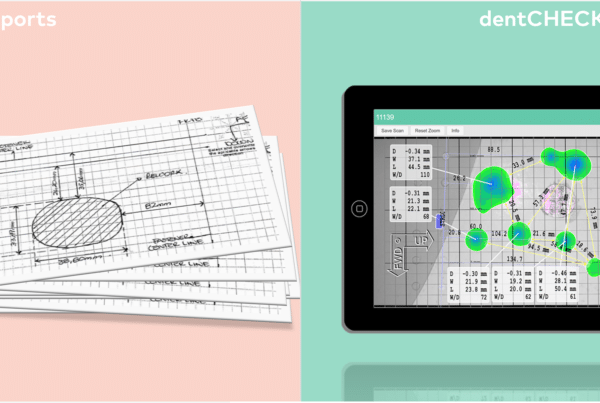

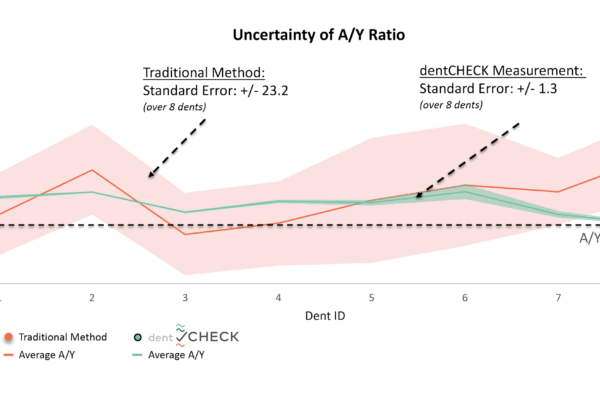

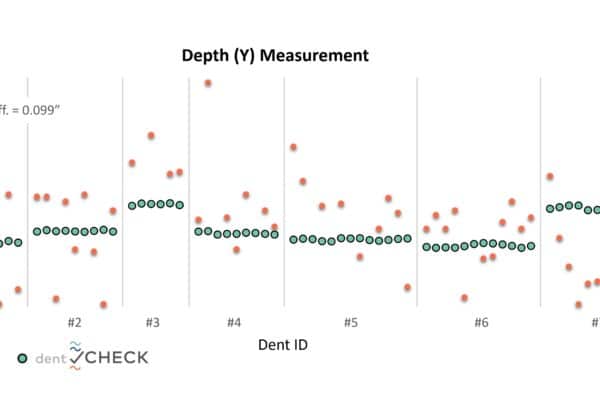

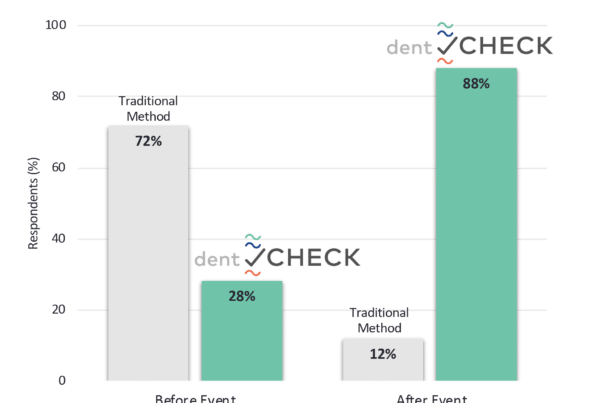

dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry. The tool delivers real-time ‘go/no-go’ answers at the push of a single-button and significantly reduces damage-mapping and reporting times, compared to traditional manual methods that use depth-gauges and straight-edges.

“HAECO’s On-wing Structure Support team is constantly looking out for new technologies to enhance our safety, quality, performance and customer satisfaction. dentCHECK has enabled us to accurately capture all the data we need and generate a report in a short amount of time. It is a tremendous advantage to support AOG situations around the clock, as well as to map extensive damages like hail strike during base maintenance input. We look forward to working closely with 8tree for future technology enhancements,” said Pierre Seon, On-Wing Structure Support Manager, HAECO Hong Kong.

“We are delighted to welcome HAECO to the global community of dentCHECK users”, said Arun Chhabra, Chief Executive Officer of 8tree. “HAECO joins the ranks of more than three dozen MROs, airlines and OEMs that use dentCHECK daily to disposition dent-damage on aircraft across the cargo, commercial, business and defense aviation sectors. We look forward to supporting HAECO’s maintenance facilities worldwide and having them experience 8tree’s exceptional customer service.”

About HAECO

HAECO Group is one of the world’s leading aircraft engineering and maintenance service providers. We provide a comprehensive range of solutions encompassing airframe services, line services, cabin solutions, private jet solutions, fleet technical management, inventory technical management, component overhaul, aerostructure repairs, landing gear services, engine services, global engine support, parts manufacturing and technical training. HAECO Group comprises 16 operating companies, employing around 15,000 staff in Hong Kong, Chinese Mainland, Europe and the United States. Learn more at http://www.haeco.com or follow us on LinkedIn and Twitter for the latest updates.

About 8tree

“Precision 3D measurement as simple as taking a photo”

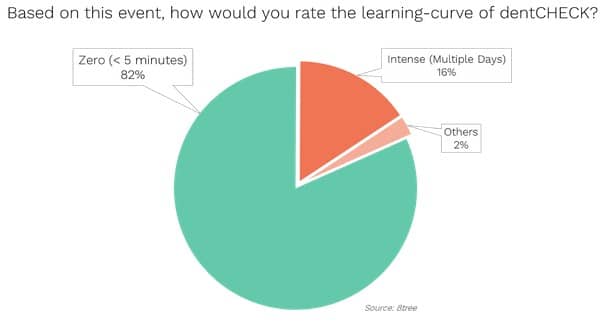

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with instantly actionable precise measurements, portability and performance. With its patented user-centric product design, instant ‘go/no-go’ answers and zero-learning curve, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.

Marketing Manager

Get in contact

LinkedIn