Joramco, the Amman-based aircraft maintenance, repair, and overhaul (MRO) facility and engineering arm of Dubai Aerospace Enterprise (DAE), a leading MRO provider in the EMEA region has chosen dentCHECK as a strategic initiative to enhance productivity within its facilities in Amman, Jordan.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, February 10, 2025.

“It is rewarding to see the growing number of MROs that are equipping their teams with 8tree’s tools to digitalize maintenance workflows. These tools have proven to increase productivity and efficiency, and they have found a place in Joramco’s hangars,” said Leonard Buck, Business Development Manager at 8tree. “Joramco’s journey has been impressive, and we are proud to play a pivotal role in their future growth trajectory.”

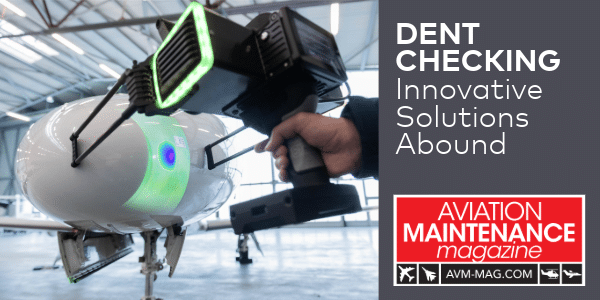

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements for critical airframe damage while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings) and eliminating human-subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo,’ and enhances safety through an improved understanding of airframe reliability.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news, follow 8tree on LinkedIn.

About Joramco

With more than six decades of experience, Joramco has built a sound track record as a leading independent commercial aircraft maintenance, repair and overhaul (MRO) facility serving a wide range of customers in the; Middle East, Europe, Asia, Africa and the CIS countries, offering services on several aircraft models from the Airbus, Boeing and Embraer fleets.

Strategically located at a free zone area in Queen Alia International Airport in Amman, Jordan, Joramco’s facility includes 5 hangars that can accommodate up to 17 aircraft with expansion plans currently in progress. Joramco is certified by a number of international regulatory authorities including the European Aviation Safety Agency (EASA), the U.S. Federal Aviation Administration (FAA) and the Jordan’s Civil Aviation Regulatory Commission (CARC).

For more information, visit www.joramco.com.jo

For recent news, follow Joramico on Facebook: www.facebook.com/joramco

For recent news, follow Joramico on LinkedIn: www.linkedin.com/company/joramco

Download the Press Release as a PDF

Marketing Manager

Get in contact

LinkedIn