8tree, a pioneer in aviation maintenance technology, is pleased to announce the integration of 8tree’s dentCHECK tool into Embraer’s aircraft maintenance services in Nashville. This tool aims to elevate the efficiency and accuracy of dent and surface inspection across Embraer’s commercial and executive jet fleets.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA – April 14, 2025.

“We are pleased to partner with 8tree to keep adopting the best-in-class tools to support our customers. We expect that dentCHECK will help us to optimize even more the efficiency of our maintenance operations in Nashville”, says Frank Stevens, Vice President of Global MRO Centers for Embraer Services & Support.

“We are pleased to partner with 8tree to keep adopting the best-in-class tools to support our customers. We expect that dentCHECK will help us to optimize even more the efficiency of our maintenance operations in Nashville”, says Frank Stevens, Vice President of Global MRO Centers for Embraer Services & Support.

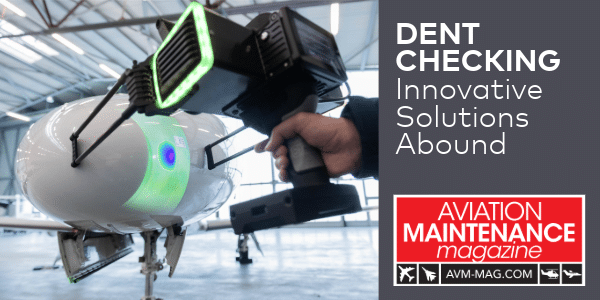

dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated augmented reality, purpose-built for the aviation maintenance industry. It delivers real-time ‘go/no-go’ answers at the push of a button, significantly reducing inspection and reporting times compared to traditional methods.

dentCHECK is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated augmented reality, purpose-built for the aviation maintenance industry. It delivers real-time ‘go/no-go’ answers at the push of a button, significantly reducing inspection and reporting times compared to traditional methods.

By incorporating dentCHECK into its maintenance processes, Embraer enhances its commitment to providing cutting-edge solutions that minimize aircraft downtime and optimize operational efficiency. This initiative aligns with Embraer’s dedication to innovation and excellence in customer support services.

Arun Chhabra, CEO of 8tree, commented, “We are excited to collaborate with Embraer in bringing dentCHECK’s efficiency and precision to their maintenance services. This partnership underscores our shared vision of leveraging technology to enhance aviation maintenance operations and deliver superior value to operators worldwide.”

The integration of dentCHECK into Embraer’s maintenance toolkit is set to commence immediately, with training and implementation phases planned to ensure seamless adoption across Embraer’s global service centers.

Learn how dozens of airlines/MROs are using dentCHECK by reading our customer testimonials.

About 8tree

8tree tools, technology and services boost your production quality with precision 3D measurement that is as simple as taking a photo.

With built-in AR, 8tree’s tools empower operators of every skill-level to achieve accurate, consistent, and actionable inspection results within seconds.

For more information, visit 8-tree.com.

For recent news, follow 8tree on LinkedIn.

Download the Press Release as a PDF

Marketing Coordinator