Ongoing innovation projects to streamline and automate surface inspection in aircraft maintenance. Meet 8tree at ATAC Conference, Vancouver (Canada), Nov 15-17 (Booth #308).

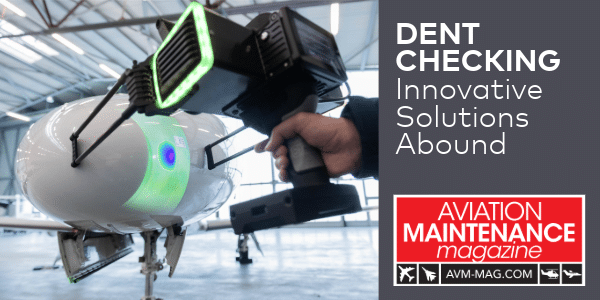

After ten years, dentCHECK is the de-facto dent-mapping tool in the aviation industry, yet the pipeline of innovation and new products to come is fuller than ever.

As the aviation sector firmly establishes dentCHECK® as the industry’s de facto tool for dent-mapping and digital reporting, 8tree enters its 10th year with an innovation pipeline that is fuller than ever.

In collaboration with the most renowned brands in aviation and aerospace – 8tree continues to broaden dentCHECK’s scope of application by introducing an array of new and innovative product features and service offerings, including the following –

-

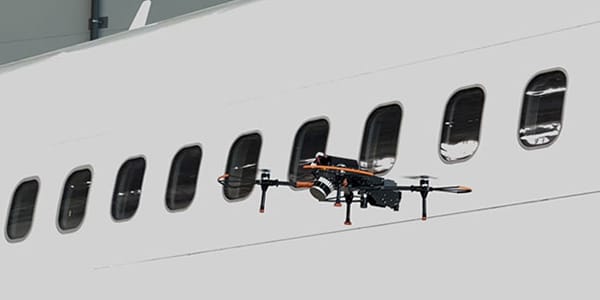

‘flying dentCHECK’ – The collaboration with Donecle entered pilot deployments this summer. The much-awaited IRIS dentCHECK drone enables automated dent detection and measurement on a large scale.

- dentCHECK’s large area dent-mapping capability is being widely used to accelerate catastrophic hail damage and expedite lease/de-lease inspections on aircraft worldwide.

- 8cloud, 8tree’s first cloud service, enables remote maintenance processes and empowers globally distributed teams to collaborate on measurement results and digital damage reports.

“Over the past decade, our pursuit of solving industry’s chronic quality and safety problems has fueled every aspect of our user-centric product design”, said Arun Chhabra, CEO, 8tree. “This has resonated strongly with dozens of our global blue-chip customers, who put their trust in 8tree tools and technology. It has also opened new doors for us, such as in the renewables sector, where our waveCHECK® tool is being embraced by leading OEMs for composite wind-blade inspection. We are thrilled that these new offerings continue to carry our tradition of reshaping industries to be more efficient and reliable.”

About 8tree

“Precision 3D measurement as simple as taking a photo”

With this vision in mind, 8tree makes 3D optical surface inspection tools that solve chronic problems for multiple industries – including dent-mapping for aviation. 8tree’s products empower every operator – from mechanics on the floor, to engineers in the lab – with actionable precise measurements, portability and performance. With its patented user-centric product design and instant ‘go/no-go’ answers, 8tree is committed to making precision 3D scanning more broadly accessible – technically and commercially.

For recent news follow 8tree on LinkedIn.