Do years of experience and skill level of aviation professionals affect the time taken to complete an inspection task?

The answer lies within the choice of tool used.

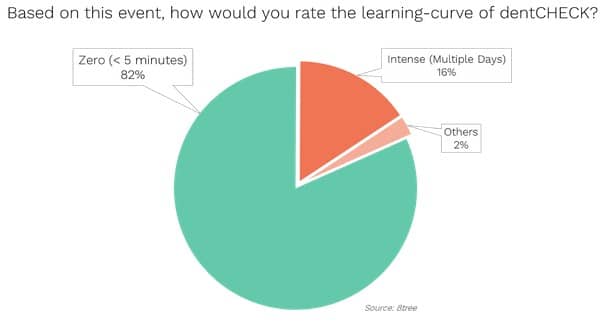

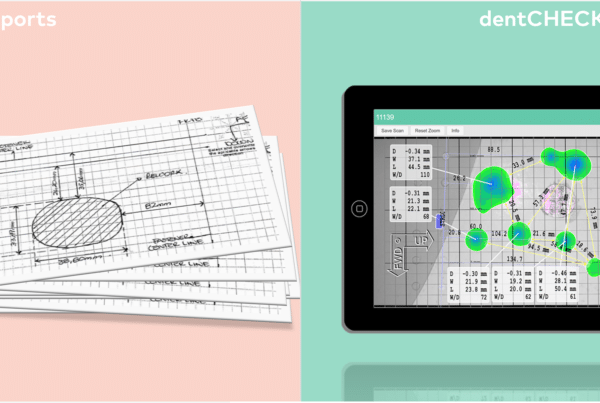

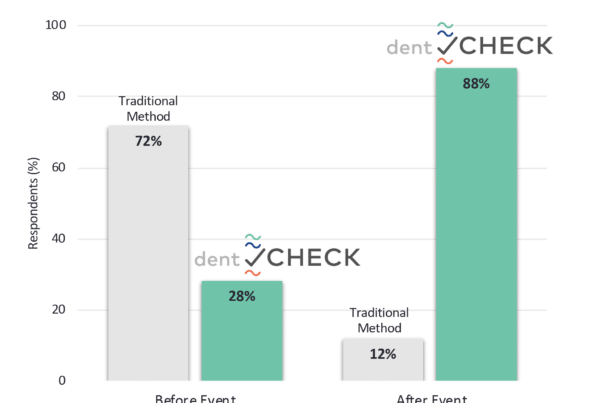

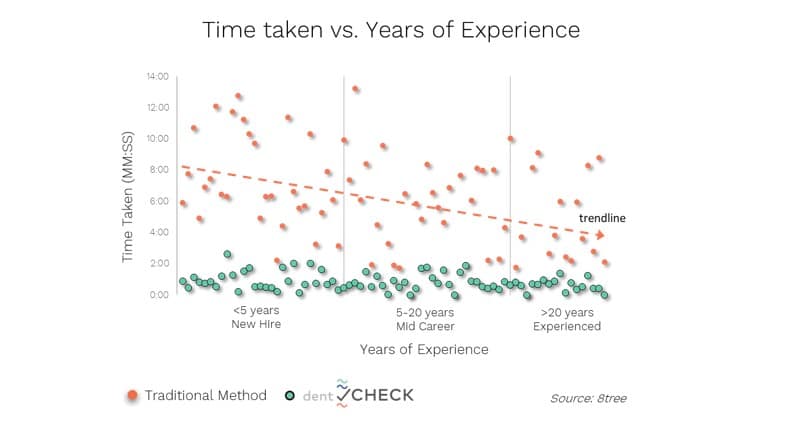

When using traditional manual methods, we saw that New Hires tend to complete an inspection task 33.3% slower than their Experienced colleagues (~7 minutes 30 seconds and ~5 minutes respectively). However, when using dentCHECK, years of experience and skill level have no influence on efficiency. Each experience and skill level group is able to complete the task in ~47 seconds when using dentCHECK, an 8x improvement when compared to traditional manual methods. Read on to learn more.

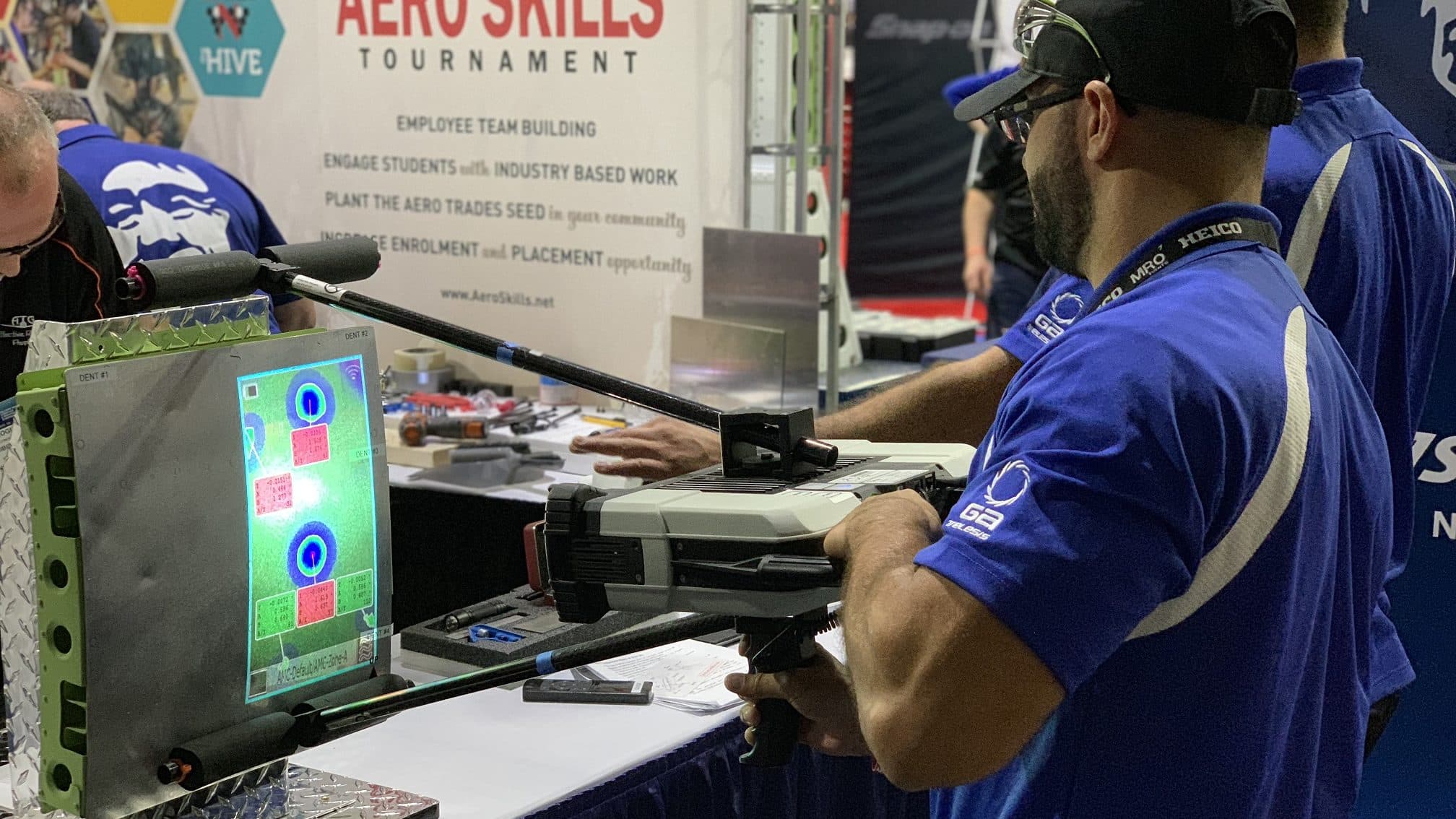

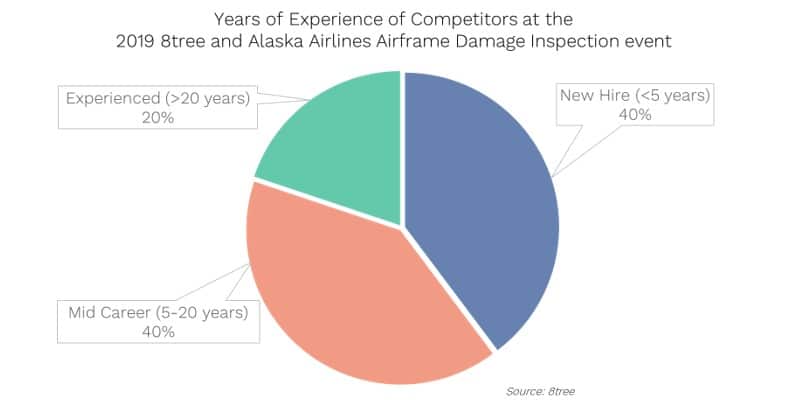

The 2019 AMC, held in conjunction with Aviation Week Network’s MRO Americas, witnessed 27 teams representing schools, 27 teams representing airlines/MRO/Manufacturing companies, and 27 teams representing the military. While the diversity of participants at the AMC is extensive, a majority of participants who participated in the Airframe Damage Inspection event represents those coming from “New Hire (<5 years-experience)” and “Mid-Career (5 – 20 years-experience)”.

So do years of experience and skill level affect the time spent to complete an inspection task? Using traditional manual methods, those with <5 years-experience (New Hires) completed the task in ~ 7 minutes 30 seconds, 33.3% slower when compared to those with >20 years-experience (Experienced), who completed the task in ~5 minutes. In contrast, when participants used dentCHECK to complete the inspection task, years of experience have no bearing on the time taken – Each experience group completed the task in ~47 seconds when using dentCHECK.

Retiring experienced maintenance professionals means that skillset that would traditionally take years to master (In this particular case, 20 years), now need to be mastered by new hires within a short amount of time. “dentCHECK is one of the more innovative pieces of hardware that I’ve seen. It should be a staple in every shop that works on aircraft”, said Trenton Blackwood, one of the student competitors from Team Tulsa Tech.

As the new generation of aviation technician – especially those still in schools – continue to view technology as a critical part of their life and work, 8tree hopes to play a much more involved role in supporting them by exposing them to advanced technology in the early stages of their career. This is accomplished by introducing dentCHECK into Part 147 schools, as well as creating opportunities for the aerospace community to experience dentCHECK at the upcoming Aerospace Maintenance Competition.

8tree is proud to once again host an event at the upcoming 2022 Aerospace Maintenance Competition. “The Aerospace Maintenance Competition is first and foremost a place where maintenance professionals showcase their ability and compete against each other. But it is also a place for the Aerospace Community to be together, to be inspired, and to celebrate the skilled craft of aviation technicians.”, said Howard Chung, 8tree’s lead in organizing the 8tree and Alaska Airlines Airframe Damage Inspection event.

Applications Engineer