Endeavor Air expands dentCHECK use to enhance the quality and efficiency of dent-mapping workflows.

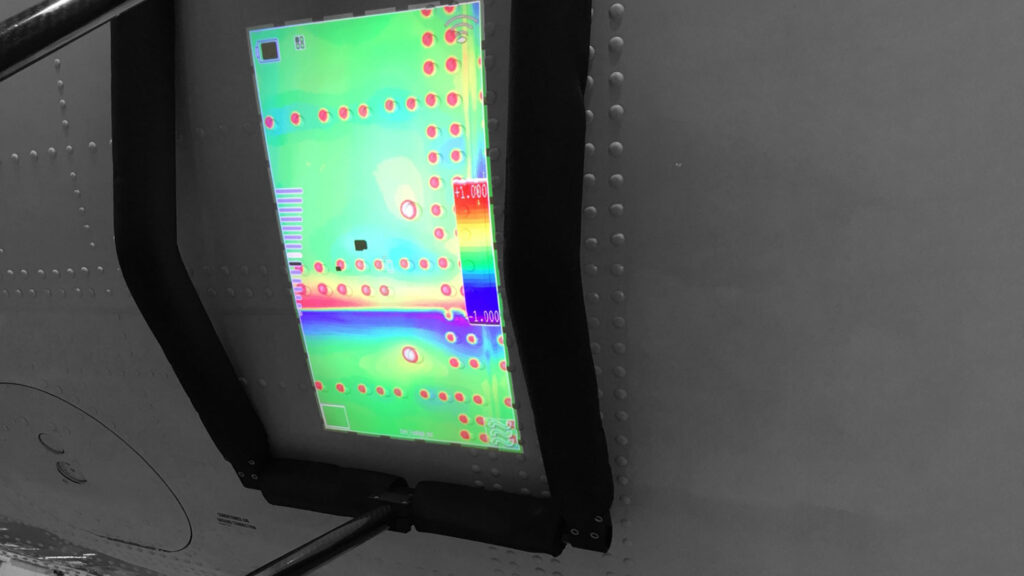

Endeavor Air has implemented dentCHECK at multiple bases to streamline dent-mapping and reporting workflows. CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, AUG 22, 2024. “dentCHECK was the right device to expand…