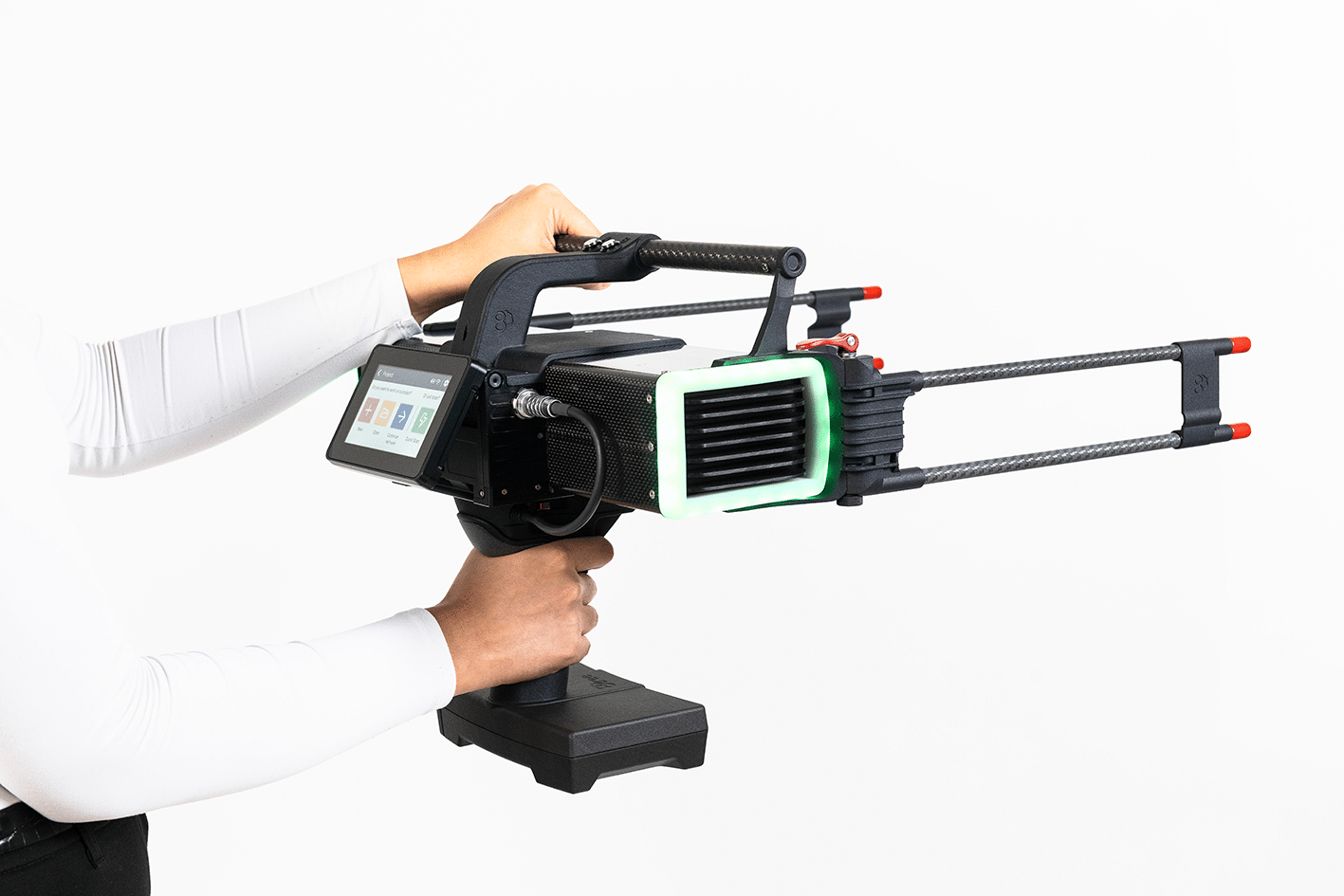

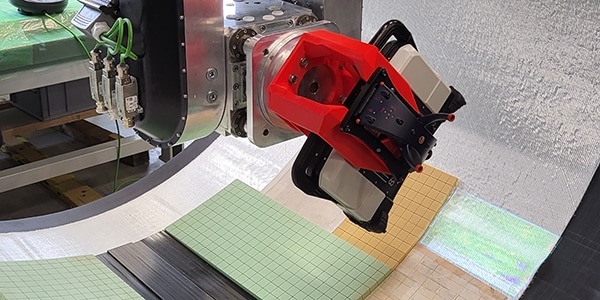

waveCHECK is a handheld-portable 3D-inspection tool for inspecting wind turbine blades in manufacturing and operation. Its efficient detection of surface defects and instant visual feedback revolutionize surface inspection.

Applications:

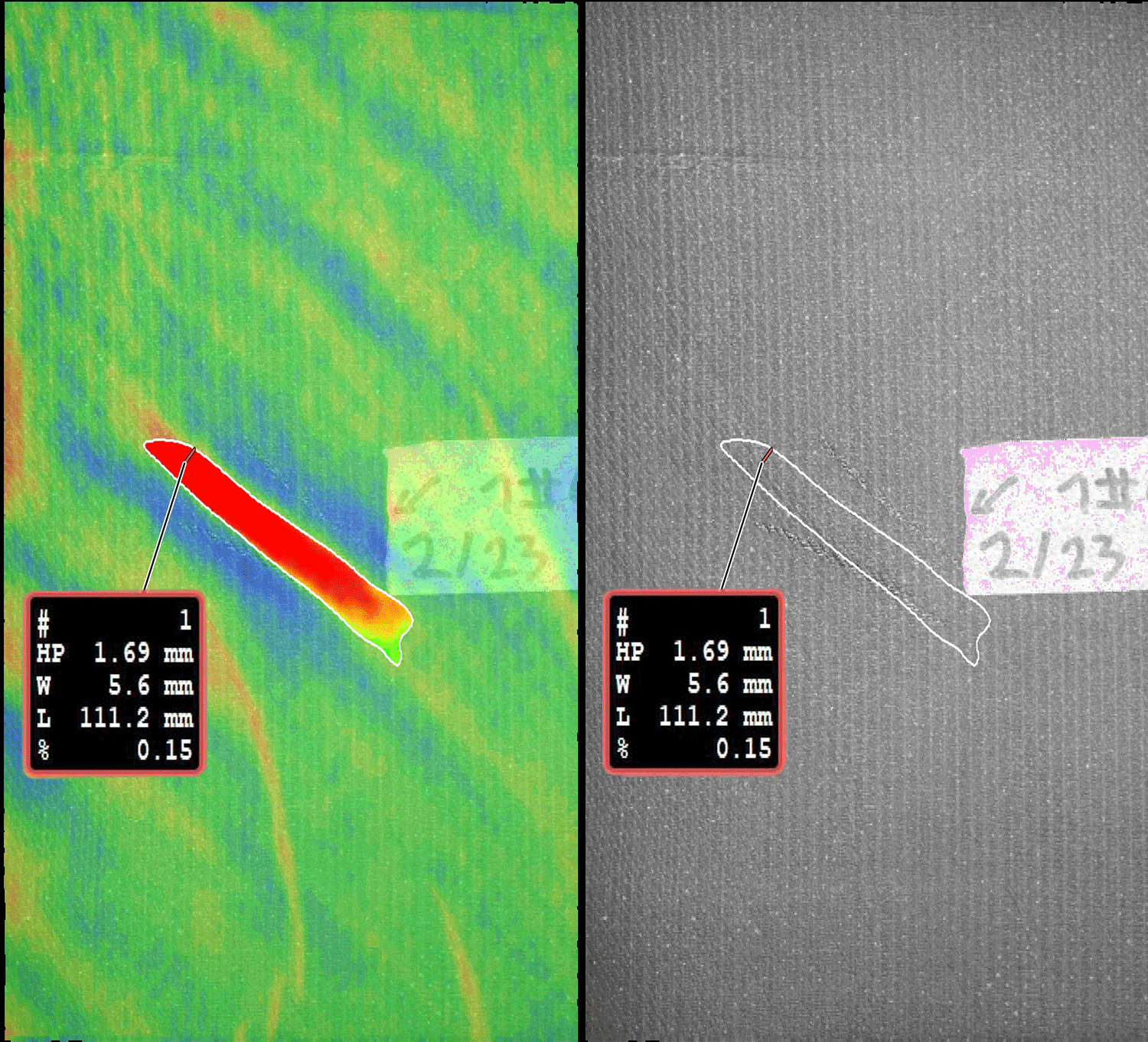

- Waves and Wrinkles

- Steps between core material panels and/or pre-fabricated components

- Gaps between core material panels during lay-up

- Flaws in paint/top coat

- Chamfers, e.g. of bond line edges

- Rain Erosion

- Any other surface damage that is reflected in the surface topology/topography