Passersby couldn’t ignore the significance of data emerging from the recent 2019 Aerospace Maintenance Competition (AMC) #AMCAero. It is tough to ignore that traditional manual measurements have 18x poorer measurement certainty than 8tree’s OEM-approved dentCHECK tool. In contrast, by delivering significantly higher consistency, dentCHECK empowers engineers to recommend conclusive corrective action for damage. Read on for the revealing analysis…

In the previous article, we examined 100 different measurements obtained from the damage-mapping event at 2019 AMC. In addition to depth and width measurements, one key criterion used to determine the corrective action for a damage is known as the A/Y Ratio. This critical metric – sometimes known as the ’Go/No-Go’ criteria – determines if a dent is classified as allowable damage, or whether it requires permanent repairs.

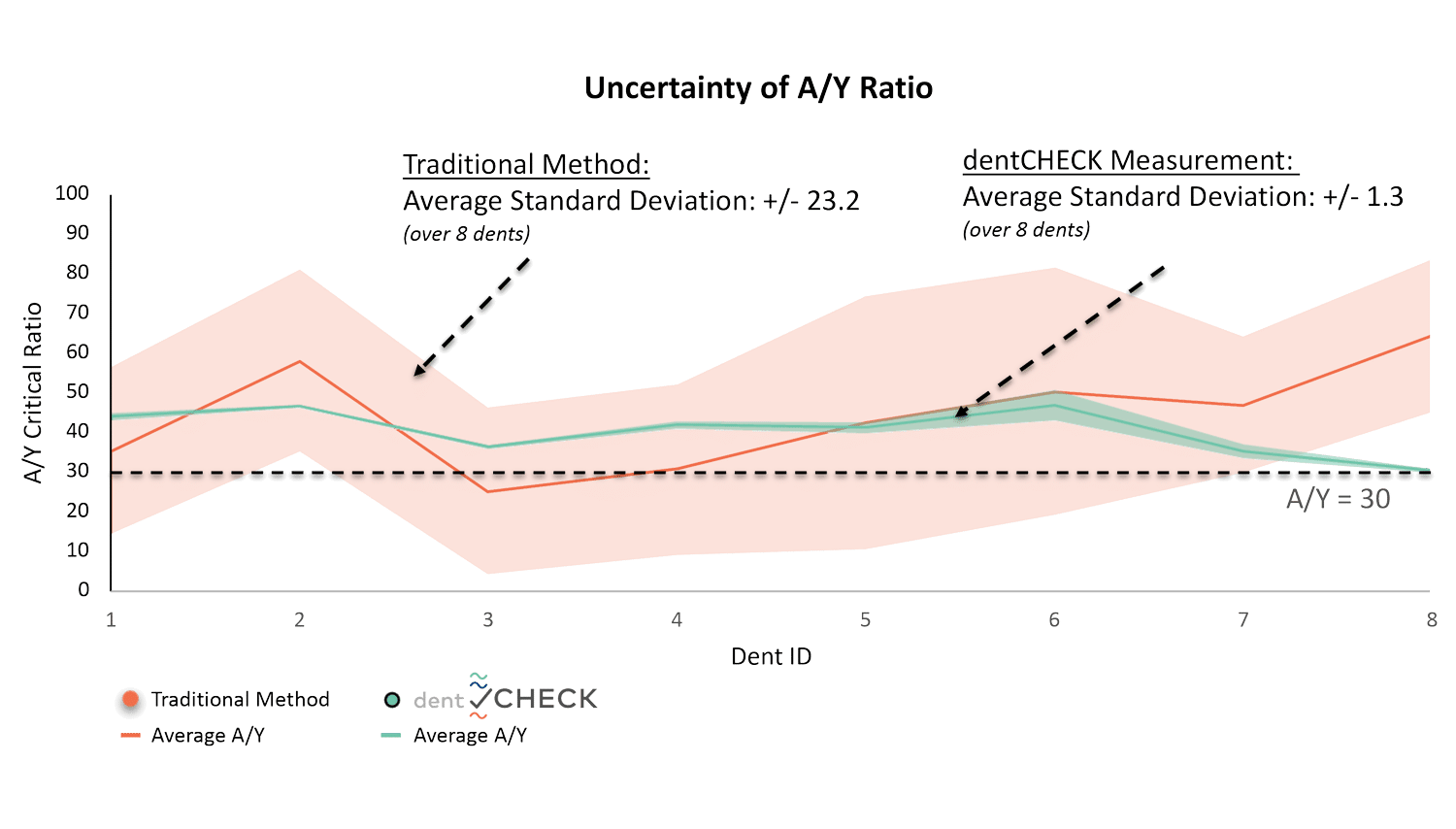

The chart* above summarizes the A/Y Ratio measurements obtained from the AMC event – on eight different dents using both traditional manual methods and dentCHECK, where the shaded areas represent the uncertainty** of each.

The chart* above summarizes the A/Y Ratio measurements obtained from the AMC event – on eight different dents using both traditional manual methods and dentCHECK, where the shaded areas represent the uncertainty** of each.

The shaded red area is the standard deviation of traditional manual methods, with an average of +/- 23.2.

The shaded green area is the standard deviation of dentCHECK, with an average of +/- 1.3.

How does this impact the resulting repair recommendations? A typical allowable limit found in Structural Repair Manuals (SRM) is A/Y of 30. This determines if the damage is permissible, requiring a detailed visual inspection every 4,000 cycles, or if it requires immediate permanent repair! A lower uncertainty of measurement ensures an appropriate corrective action.

This isn’t just about grounding or putting an aircraft back into service, but more importantly, it is about aircraft safety. Which method would you opt for to recommend a conclusive corrective action – a method with an error of +/- 23.2 or a ‘Go/No-Go’ tool that delivers 18x greater certainty?

But how can we believe the measurements? Simply relying on spec-sheets and the promises of equipment manufacturers is inadequate and can be especially dangerous when dealing with aviation safety. A neutral industry-backed reference standard is a must. The measurement integrity of dentCHECK is guaranteed by a precision-manufactured validation reference plate that is backed by national lab standards. dentCHECK is the world’s only ‘built-for-aviation’ 3D damage assessment tool that comes with an OEM-approved reference standard to ensure the validity of every measurement.

What is the big deal? An accurate, reliable and consistent inspection result is needed before ANY corrective action is made – and dentCHECK delivers, which is why it is the preferred tool amongst AMTs and engineers.

Stay tuned in the coming weeks as we discover the impact of dentCHECK on inspection time, importance of user experience with tooling and the necessity for a reference standard.

* A/Y > 100 are considered outliers and are not included in this study.

** Uncertainty here is defined by the Standard Deviation of each set of sample.

Co-Founder & CEO