What makes us different

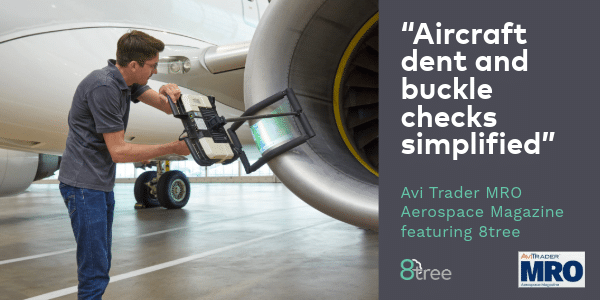

1-button operation

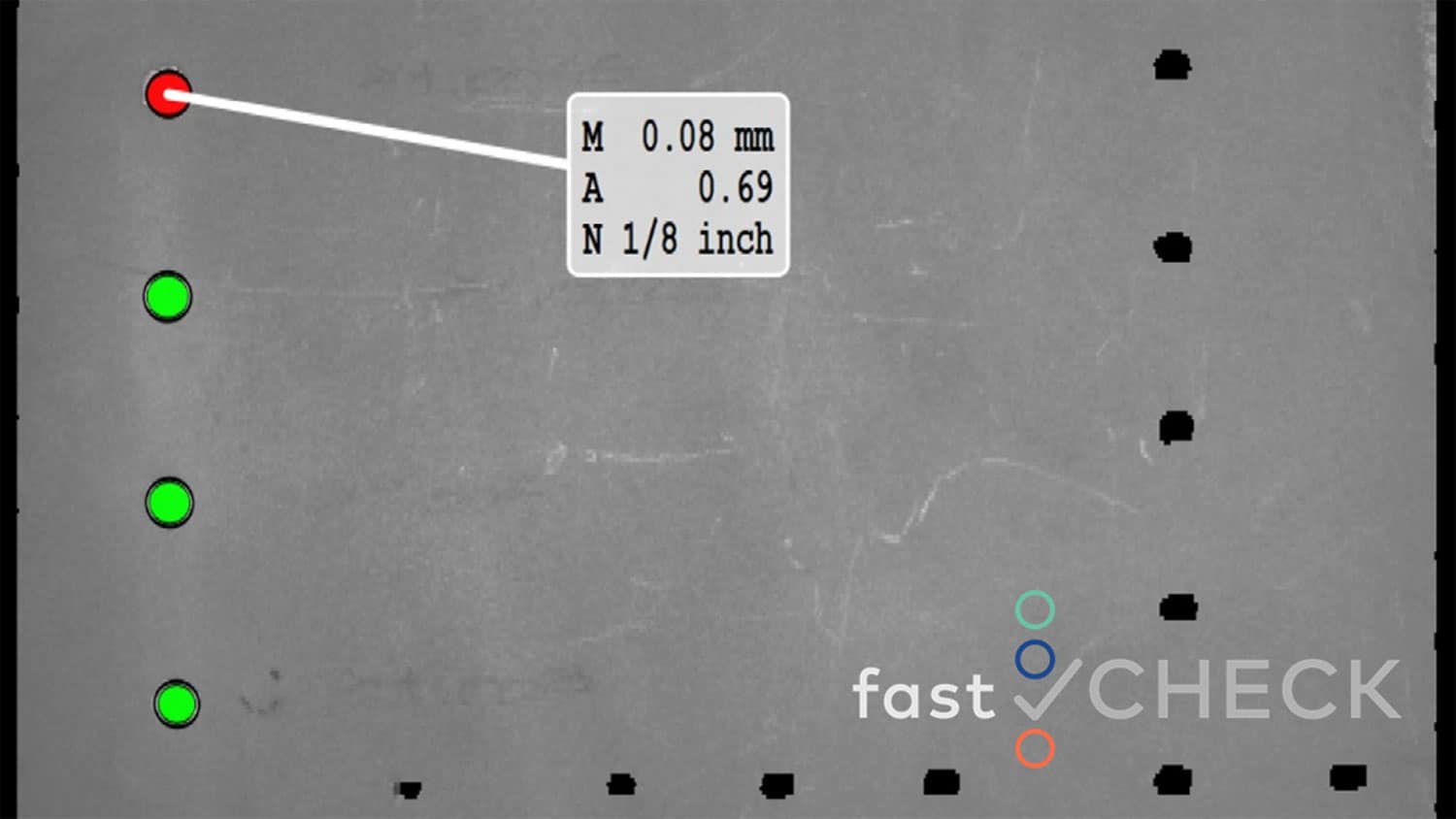

Instantly actionable results

Performance traceable to national standard

37x better measurements than traditional methods

10x faster mapping + reporting than traditional methods

No post-processing,

no surface preparation,

no programming

End-to-end digital workflow

Solutions

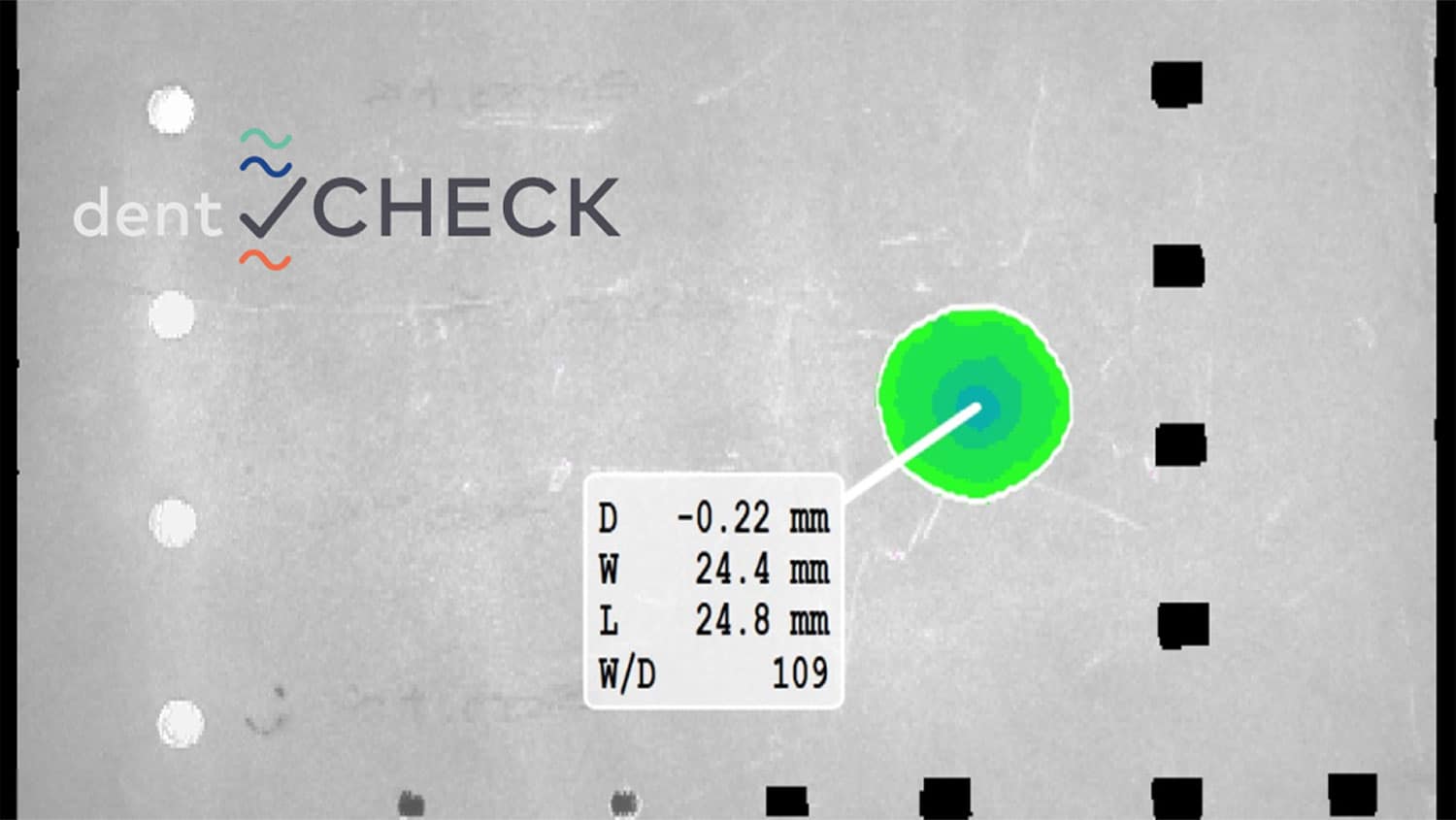

- Mapping of surface defects >> dentCHECK

- Check fastener flushness >> fastCHECK

- Quantify wrinkles on composite laminates >> waveCHECK

- Assess surface alignment and steps >> stepCHECK

- Contrast manufactured parts against references >> compareCHECK

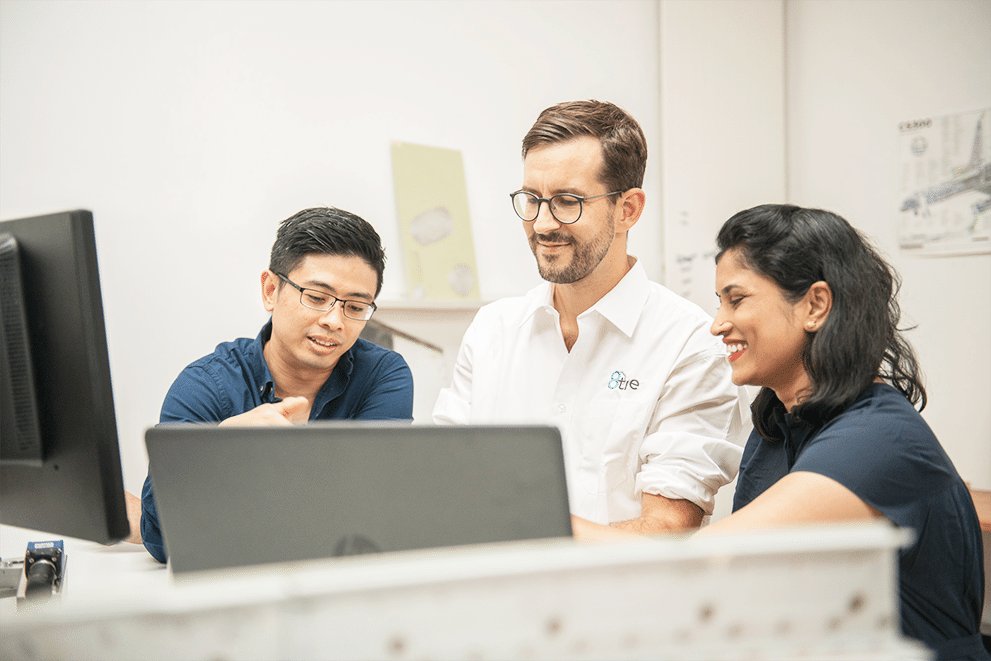

Careers

Do you want to be part of a dynamic, young company? Are you ready to reshape how traditional industries solve problems? Are you interested in cutting-edge topics like 3D imaging, augmented reality, cloud computing and artificial intelligence?

Then 8tree might be the right place for you. We are always looking for new talent! Learn more